Research activity of the department of composite and carbon materials is oriented to theoretical studies and applications of modern nano-fibre, nano-particle and hybrid composite materials prepared on the basis of synthetic or inorganic materials and materials of organic origin. This activity includes two main directions, first composite materials for medical use on the basis of a biocompatible and biodegradable matrix, and second technical heat resistant composites with a matrix of ceramics.

Composite materials for tissue engineering and medicine

The Department of Composites and Carbon Materials works on biomaterials for potential substitutes for both soft and hard tissues, and develops materials that are as similar as possible to natural tissues from the viewpoints of their mechanical and structural properties and material composition. Concerning hard tissues, a focus is paid on the main components of bone, namely collagen and calcium phosphates that are process at the nanoscale at which they occur in natural bone.

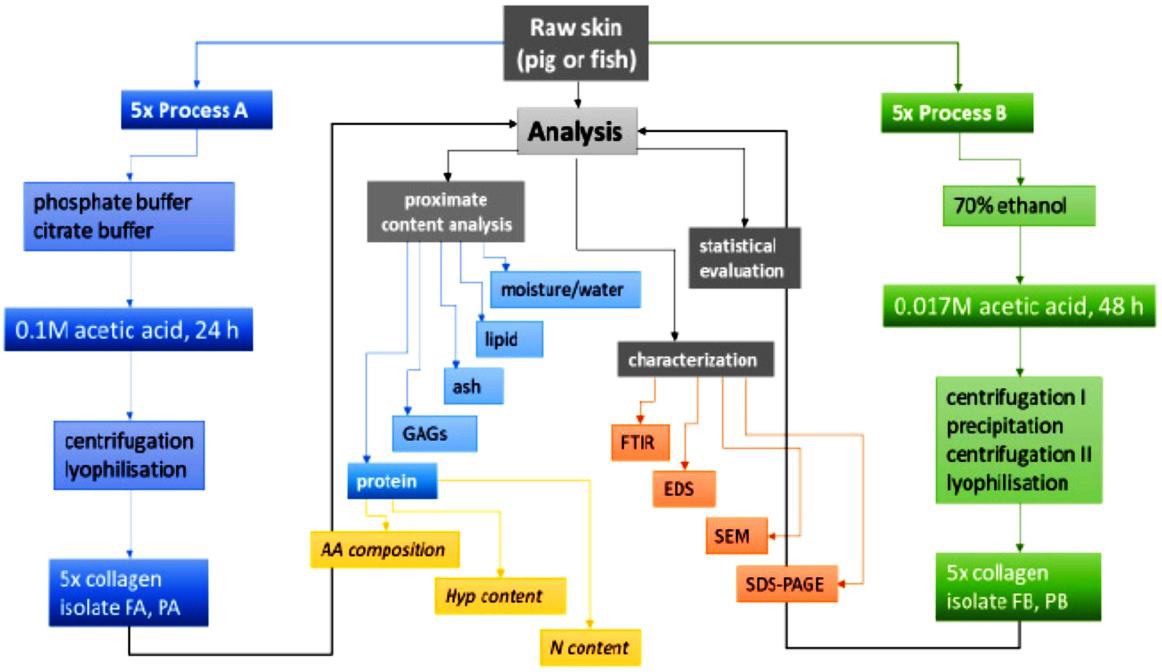

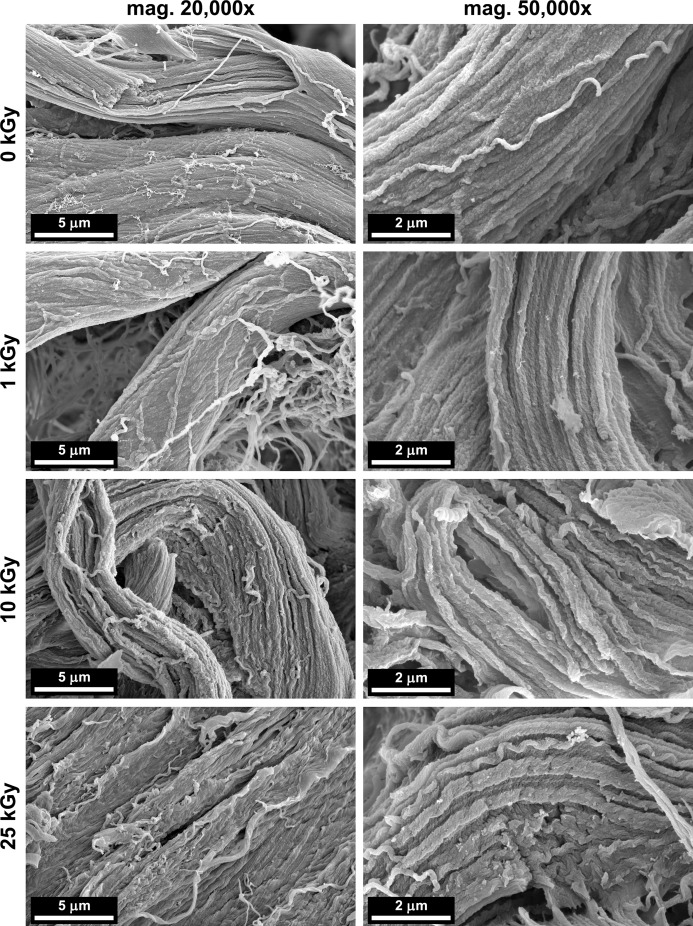

1. Isolation, processing and characterization of collagen

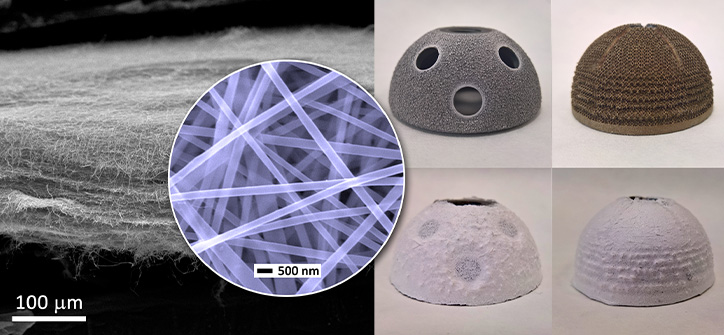

Collagen, a unique natural polymer with a complex hierarchical structure and outstanding properties, constitutes a potential candidate for the construction of materials for use in the field of bone tissue regeneration. With respect to the limitations imposed by the complex processes applied in the processing of collagen from native tissue to the intended form, its application is limited. It is important that the balance be maintained between the successful processing of collagen into microstructured and nanostructured constructs and the preservation of its unique structure without some degree of denaturation.

2. Calcium phosphate nanoparticles for the repair of bone defects

Calcium phosphates (CaP) have traditionally been used for the repair of bone defects due to their strong resemblance to the inorganic phase of the bone matrix. The wide variety of natural and synthetic CaP‐based biomaterials available today are used extensively in dental and orthopaedic applications owing to their high levels of biocompatibility, osteoconductivity and osteoinductivity. Various calcium phosphate calcium phosphates were isolated and utilized in order to obtain a suitable filler for the studied biocomposites. Bioapatite isolated or prepared from biogenic sources exhibits enhanced resorbability and a much higher degree of bioactivity than synthetic calcium phosphates.

3. Collagen-calcium phosphate nanolayers with controlled elution of antibiotics

Collagen/calcium phosphate/antibiotic coatings for orthopaedic implants in the form of a nanofibrous layer exerts a strong local anti-infection effect without indication of cytotoxicity and, simultaneously, leads to an increase in the rate of osseointegration necessary for the suitable fixation of the implant. It is expected that such a layer will be used particularly in the case of known prosthetic joint infections or as a preventative procedure regarding primary joint replacement in a potentially infected site.

4. Collagen composite scaffolds for bone surgery

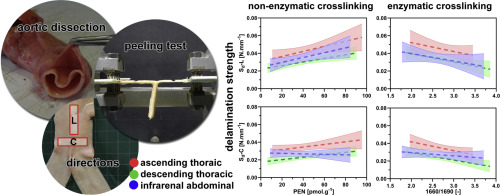

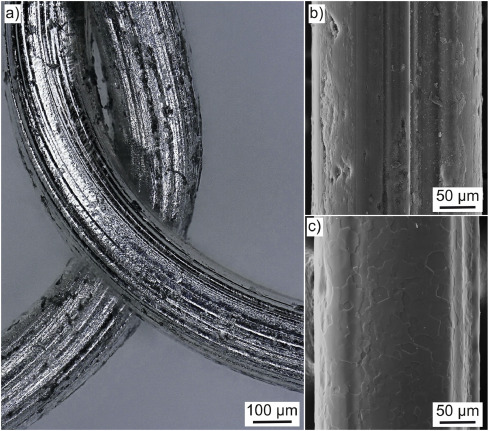

Optimal bone replacement materials imitate the real bone composition and structure so as to allow for the functioning of repair mechanisms by providing a temporary porous scaffold that, in turn, provides mechanical support for cells up to the time that the tissue has regenerated and remodelled itself naturally. The application of collagen is problematic due to its poor mechanical properties, high swelling rate in aqueous environments, low structural stability and low level of resistivity to the enzymatic degradation of its untreated laboratory form. We demonstrated that the mechanical and structural properties of collagen can be improved via chemical cross-linking and via the creation of composite materials in which the collagen matrix is reinforced by polymeric fibres or calcium phosphate particles.

5. Collagen porous foams for wound healing

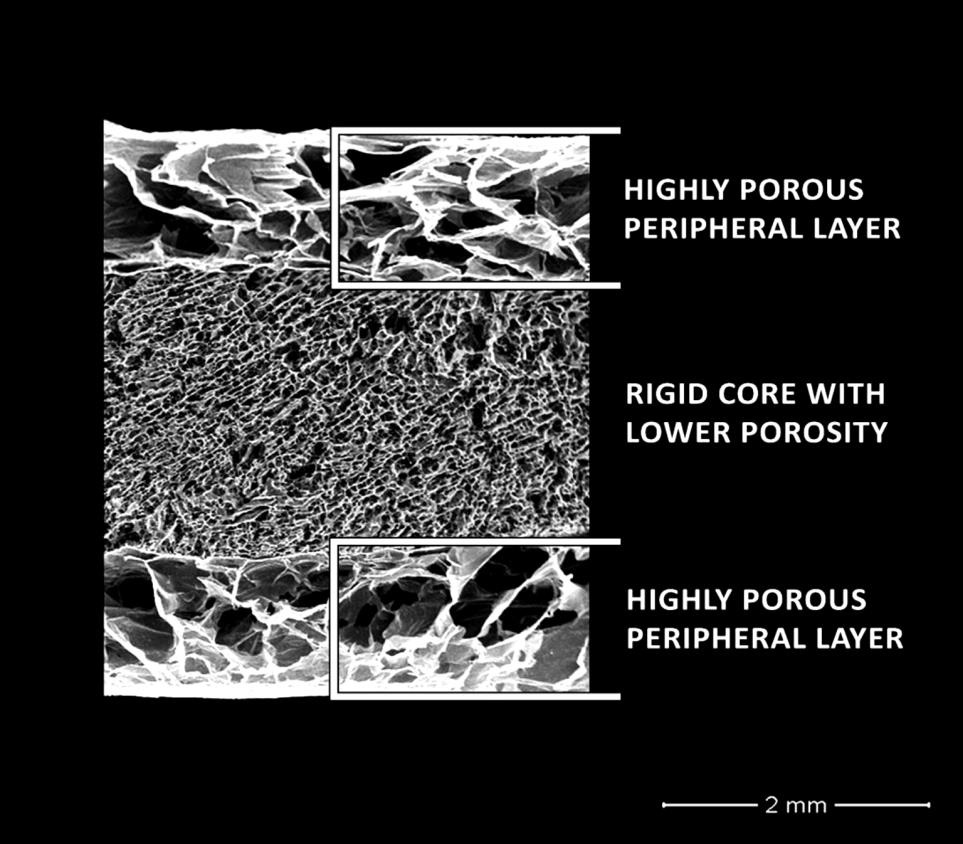

Collagen antibiotics-containing foams provide a promising tool for the local treatment and prevention of surgical site infection. Advantage of utilization of fish collagen, isolated from freshwater fish (Cyprinus carpio) skin, remains in lower antigenicity than its mammalian counterparts, low risk of the transmission of ruminant zoonosis, excellent biocompatibility, and promotion of direct cell adhesion and differentiation. Various construction of foams was developed and analysed in combination with different kinds of antibiotics, namely simple homogeneous foams, sandwich foams with variable porosity or composite foams prepared as combination of collagen nanofibrous reinforcement embedded in porous collagen matrix.

Research of preceramic polymers and their use in the development of ceramic foams, ceramic matrix composites and all-ceramic sandwiches

The Department also specialises in the development of unique composites for use at elevated temperatures. Such composites are produced from a range of fibres, e.g. basalt, glass and ceramic fibres, and are fabricated using ordinary laminating technology. They are then subjected to high temperatures in an inert atmosphere which significantly enhances their properties. We made particularly significant progress with so-called partially-pyrolyzed composites which are reinforced with basalt fibres. These materials have good mechanical properties and, unlike other fibre-based composites, they also exhibit a high degree of fire resistance.

1. Advanced ceramic foams from a pyrolysed polymer precursor

The research of the pyrolysis transformation of polysiloxane thermosets into Si-O-C ceramics is focused on simple basic polymethlylsiloxane and polymethyphenylsiloxane resins. The effects of the pyrolysis process on changes in the chemical structure of the material and on induced changes in mechanical properties at various degrees of this conversion in the range of 250 to 1000 °C have been investigated. Long-term experience with pyrolysis processes and newly acquired knowledge in the field of pyrolysis of polysiloxanes were used in the development of advanced ceramic foams, several principally different methods of cross-linked polymer precursor preparation have been tested, namely expansion of simple low molecular weight hydrocarbon compounds, utilization of epoxy particles as pore-forming templates or adding starch into the thermoset precursor prior its curing.

2. Ceramic sandwich materials

The experience with the production of ceramic matrix composites and the knowledge gained in the field of ceramic foam preparation are utilized in the development of sandwich material, all components of which are made of ceramic. A ceramic fibre reinforced composite with a nanocrystalline mullite - corundum structure was used for the outer bearing layers of this sandwich. The matrix of the bearing layers is formed of Si-O-C ceramics. The outer bearing layers were made separately by placing the fibres into a polysiloxane thermoset and its subsequent pyrolysis to 1000 °C. The core of the sandwich is formed of Si-O-C ceramic foam which was prepared by foaming the polysiloxane precursor by the addition of starch and subsequently pyrolyzed to a temperature of 1000 °C. The outer bearing layers were adhered to the foam core with an inorganic silicate adhesive and subsequently the sandwich was annealed to 1000 °C to cure the adhesive.

International Cooperation

Physics, Vienna, Austria

Development of tissue engineering materials on the basis of polymer matrices and mesenchymal stem cells, osteoblasts and fibroblasts, (2012-2014), Dr. V.E. Yudin, biomaterials which consist of chitosan and other biocompatible matrices